Pipeline direction inspection

Pipeline direction inspection

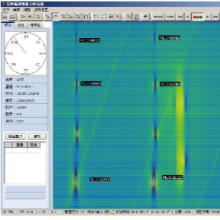

Process of pipeline deformation and direction inspection: 1. Before launching the inspection tool, record the coordinates of the starting position according to the GPS base point. 2. After launching the tool, the inertial navigation inspection will start to continuously record traveling track, and the pipe deformation and displacement change data collected by the tool. 3. When the tool passing the through the AGM, it will correct the operating parameters of inertial navigation according to the coordinates set by theAGM, so as to minimize the error of movement track. 4. After recovering the tool, the engineering personnel will extract the recorded data. 5. Send the data to the pipe data analysis system to analyze, classify and distinguish, and finally generate the customization report.

Inertial navigation data analysis system: based on years of detection experience of our company, and combining with foreign advanced software development technology, we developed Mapping Tool data analysis system and combined IMU, Record, AGM, GPS and other information units to optimize and integrate the collected data. This system can correctly judge and analyze the pipe deformation, positioning and direction.